With the rise of the live broadcast industry, more and more musicians are active on major live broadcast platforms, and gradually return to the public eye through online concerts, fan clubs, fan meetings, etc.

If you want to do a professional music live broadcast, we need to prepare various equipment and accessories such as condenser recording microphones, professional sound cards for online live broadcasts, laptops, in-ear monitoring headphones and microphone cables.

Connect these devices with professional cables. To ensure that there is no noise, audio distortion, etc. during the connection process, the choice of cables is crucial. There is a saying in the industry that is often heard by everyone: 70% of the problems that occur during the operation of the equipment are caused by connection problems, and this is often overlooked. So for ordinary consumers, with so many cables on the market, how do we choose a professional microphone cable?

Some users think that the microphone cable should be thick and the quality is reliable. Is this true?

1. Appearance

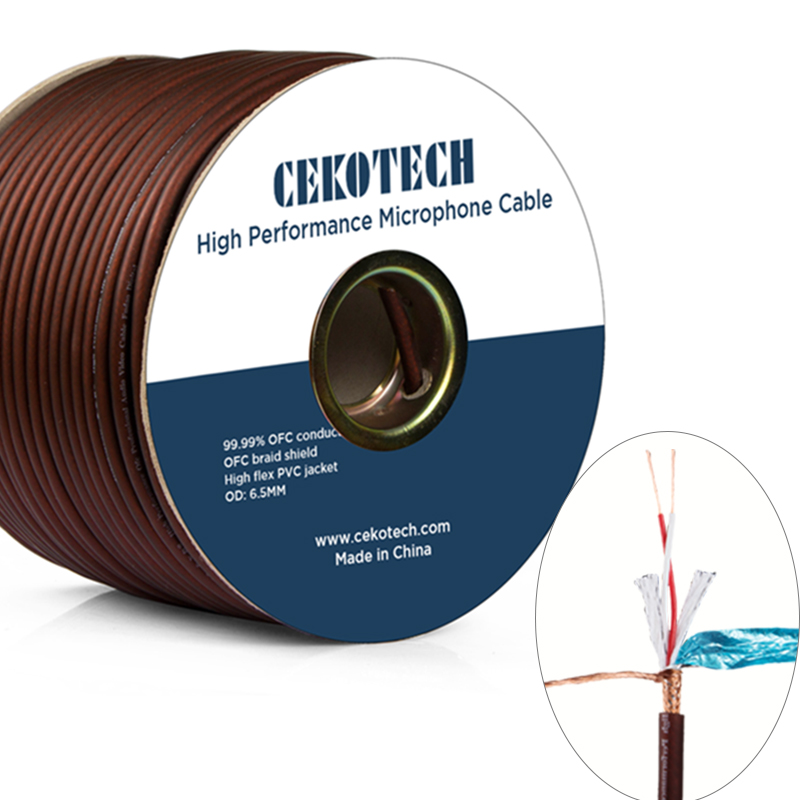

The basic structure of the microphone cable is sheath, shielding, insulation and conductor from outside to inside.

The outermost sheath, the sheath material is elastic PVC, which is more elastic than ordinary PVC and also soft. It plays a role in protecting the internal structure of the cable. A good sheath is beautiful, elastic, smooth, dirt-resistant and easy to maintain, and is tensile and compressive during use.

2. Anti-interference

A good sound should be clean, clear and three-dimensional. However, in daily use, noise, sound distortion and other situations are often encountered. What properties of the cable are related to this?

The anti-interference and low attenuation of the cable correspond to the internal shielding, insulation and conductor. Let’s introduce it in detail.

The interference of the signal includes electric field, magnetic field and electromagnetic wave. The main way to resist interference of the cable is the shielding layer. The shielding method of the microphone line is commonly used as copper wire braided shielding and copper wire winding shielding.

The two are distinguished from the use scenario. The braided shield is tensile and drag-resistant, with high strength, suitable for repeated retraction; the winding shielded microphone cable is softer and suitable for occasions with high bending requirements, but the shielding effect is slightly inferior to the braided shield when bending. These two shielding methods use copper wire materials, so the cable price is higher.

Some manufacturers use aluminum foil shielding to save costs. The advantages of aluminum foil shielding are full coverage and cheap materials. The disadvantage is that after repeated bending, the shielding effect is greatly reduced. Therefore, it is suitable for fixed installation of audio signal lines, but not for microphone cables.

In order to save costs, some manufacturers try to reduce the number of copper wires or the diameter of copper wires as much as possible, which will deteriorate the shielding effect or even eliminate the shielding effect.

The shielding effect is judged by the shielding coverage rate. In JB/T 8734.1, the braiding (or winding) density of the shielding for polyvinyl chloride insulated cables and cords with rated voltages of 450/750V and below should not be less than 80%.

3. Low attenuation

The high-frequency part of the sound adds a lot of points to the music. If the high-frequency attenuation is large, the music will lose its luster. A good microphone cable has clear high frequencies without attenuation, which means that low-attenuation polyethylene insulation materials are used.

Post time: Jul-15-2024